Search the Community

Showing results for tags 'waterfowler41'.

-

SCROLL TO BOTTOM FOR MY FEEDBACK ON THE KIT I purchased the Eibach Pro Truck lift kit the other day so below is a quick how to on the process and some initial feedback I have on the kit. My truck has 75k miles and I knew before purchasing anything I had a blown rear shock. I wanted to lift my truck higher so instead of purchasing OEM equipment and adding more rough country spacers (already had a 2" lower up front), I saw the Eibach kit. It included everything to complete a reasonable 2.5" lift AND included new springs for less than $600. From my tuner days, Eibach was the go-to for lowering springs, I assume they know what they are doing plus they are American made, can't go wrong. The struts are adjustable like Bilsteins so this was the best option for achieving the lift I wanted. With the Eibach springs and the struts at their lowest setting, my truck would be 2.5" higher according to the instructions. Also, the rear shocks in the kit, safely handle a +1" lift in the rear. This is what I wanted! Since I was already touching every other suspension component, I figured I might as well add the 2" rear blocks I've been eyeing so I bought those direct from RC. Truck set up before project: 20" wheels, Falken AT3W 33" tires, RC 2" lower spacer with stock struts and shocks one of which is completely blown. The ride was sloppy, pulling into driveways or other major bumps my truck was rocking and rolling, signs my stock set up was done. I would wince before hitting large bumps on Chicago expressways knowing my cage was about to get rattle. The 20" wheels and heavier tires aren't helping but the dampers needed to be retired. Purchased parts: Eibach Pro Truck Lift kit: E80-23-006-02-22 Includes new springs, new monotube struts, and new monotube rear shocks. Also includes new king nuts for struts and bump stop collars for reusing OEM bump stop. https://eibach.com/us/i-8809-pro-truck-lift-system-stage-1.html Rough Country: 6532 (2" rear blocks) Includes new u-bolts, washers, nuts, and 2" tapered rear blocks No link, this is the rear blocks from their leveling kit, you have to order over the phone. Side note, RC folks are REALLY nice on the phone. If your are uncomfortable working on compressed springs do not attempt the strut disassembly yourself. Take them to a shop. I've done several spring projects in my life and understand how dangerous they can be. Be safe and take the necessary precautions and where the right PPE. If the compressors fail, they should fail in an open area, not in front of you. Prepare for the worst, hope for the best. I am not responsible for misuse of the below info. Important tools: Eye protection and hand protection Pneumatic gun Spring compressors pry bar jack and jack stands Sockets 10 mm and 15 mm all the way up to a deep 22 mm Wrenches 15 mm all the way up to 22 mm A friend, loved one, kid, someone to help. I did this work by myself and it took me probably 6 hours in total, would've been half that with a second set of hands. Before you do any suspension work, always take measurement from fender to ground or from fender to top of wheel. This gives you baseline measurements to calculate your final lifts. Rears (blocks and shocks): 1. Jack your car up on both sides. Put on jack stands. You want the rear axle to drop straight down. Only doing one side at a time will be an issue, I learned the hard way. 2. Doing one side of the truck at a time, remove the upper shock bolt (the nut is welded, just remove bolt) and the bottom bolt/nut. Shock should pop right out with some love. 3. Place a car jack under the differential. Remove the (4) 21 MM bolts on the factory u-bolts. Again only on one side at a time. 3. SLOWLY lower the rear differential to allow enough room to remove the stock blocks. Watch your brake lines, you have some play but not too much. 4. Before installing the new block, clean the alignment pin and hole on your truck. Mine had a lot of dirt and salt. A wire brush cleaned it right up. I also sprayed it down with WD40 for good measure. 5. Once the block is installed and lined up, slowly raise your diff back up. If your blocks are tapered make sure the taller side of the block is closer to the rear of the truck. Install the new u-bolts and torque the new 22 mm nuts down in an alternating pattern. Old block next to new blocks below. 6. Install the new rear shocks, start at the top then do the bottom. I had to compress the shocks about 1/2" to get the bottom bolt in. 7. Repeat on other side then your done. I took the truck for a quick test drive to test out everything. No shutter, no issues. Picture below of my old shocks next tot he new, one looks blown... Time for the fun part, the fronts! Fronts (struts and springs): 1. Unbolt the 3 nuts on the top of the strut. Easy access through the engine bay. You can remove these before the car is lifted without issue. Leave the outside nut hand tight to prevent your strut from dropping out. 2. Jack up one side of car and remove wheel. 3. Unbolt the sway bar end link, tie rod end, two bolts on bottom strut mount, and the upper control arm ball joint. The UCA will need a BFH (code for hammer) to help it out. Leave the nut finger tight so the UCA doesn't shoot out of knuckle right away. Some people say you can do this without removing the UCA but I just couldn't see how that could be done in my application. 4. If you're by yourself place a car jack under the knuckle, remove UCA ball joint nut and slowly lower front hub assembly, there should be plenty of room to remove the strut now. I used a jack stand to hold the hub assembly while I unscrewed the top nut on the strut and carefully remove it. Once the strut is out, loosely reattach the UCA to the hub so you can leave it for a while. 5. With a permanent marker, draw a line down the strut assembling marking everything. The line should be on the outside face of the strut assembly. This is your index line, when you transplant these pieces to your new strut they should all line up. If they don't you messed something up. 6. Now the dangerous stuff, install your McPherson spring compressors on the stock spring, try to grab coils that are far from each other as the spring will be easier to compress. Compressors should be 180 degrees from each other to ensure even loading. 7. Put on all your PPE, say a pray, and start tightening the spring compressors until you see a gap between spring and strut per mounts. Treat loaded springs like a gun, never point it at anyone and try not to drop it, jostle it, anything that could affect the compressors grip. Personal note, when I am doing dangerous stuff in my garage I either text someone letting them know what I am doing and text them after I am done or tell my wife if shes inside to check on me occasionally. 8. After you remove the king nut, open up the compressors, you can toss the springs. You will need to remove the upper assembly of the strut (top mount, bracket, spring boot, and bump stop). You will also need to remove the lower spring perch. Do this by gently tapping the perch towards the top of the strut to release it. PB blaster helps speed this up. 9. Prepare the Eibach struts. These are adjustable to dial in your final ride hide. In my application, when used with Eibach springs, the bottom level (lowest setting) will achieve a 2.5" lift up front. Snap ring was moved into the bottom grove and collar installed. The lower perch from OEM strut was installed. 10. There is a metal collar inside the yellow bump stop, pull this metal piece out and replace with the one supplied by Eibach. The shaft is bigger on Eibach struts so the collar needs to be upsized. 11. Dangerous part 2, install the compressors on your Eibach spring. Again try to grab coils that are far apart to ease the compression process. I believe the springs needed to be compressed 1/2" to fit on the strut. This was the most nerve wrecking part of this project. The compressors have seen better days. Those bends are pretty ugly. 12. Once compressed start lining up the strut, inside rubber boot, bracket, and top mount. Your line you drew earlier should all line up with the outside face of the strut. Make sure the bottom of the spring is fully seated on the perch plate. 13. Install top metal spacer/washer from OEM strut and new king nut provided by Eibach. Tighten down nut then your good to unload the springs. Once the springs compressors are removed the scary part for that strut is over. 14. Remove the nut on the UCA and reinstall your strut. Have at least one bottom strut mount bolt available so once you get the strut lined up, you can throw a bolt on the hole to keep things in place. 15. Reverse the beginning steps with the reassembly of the hub parts. You'll will need a pry bar braced on the spring to hold the UCA down firmly into the top of the hub so you can tighten the nut without the ball joint spinning. 16. Repeat on other side. 17. Take your truck for a quick test drive, if no noises or issues, take in for an alignment. 18. Take final measurements to confirm relatively even lift. Drivers side may be lower due to gas tank. Final thoughts on the upgrade: I am absolutely in love with the kit. I've been putting off replacing shocks for a while, so glad I finally did this project. Dare I say, Eibach MDFA? (Made Driving Fun Again...) Like I mentioned above, I was beginning to notice I was wincing before hitting big bumps because of how loosey-goosey my suspension had become since I bought it. The Eibach kit firmed up the ride noticeably. At slow speeds I do feel small bumps which is a given with monotubes, 20" wheels, and aggressive tires. At speed, the dampers turned those crazy earth shattering/dash destroying bumps on Chicago expressways into muffled bumps on the road. Also the dampers recover quickly. Driving into parking lots or steep driveways, my truck you to rock back and forth, now the truck rocks and correct quickly. No over correction. I would highly recommended this kit as an alternative to the Bilstein kit. If your looking to lift your truck, its hard to beat this package. Overall very happy with the kit and how it turned out. Excited to get some off road time this hunting season! I filmed the install and will be posting the video when its edited. Thanks! WF41

- 116 replies

-

- 7

-

-

-

- eibach

- waterfowler41

-

(and 2 more)

Tagged with:

-

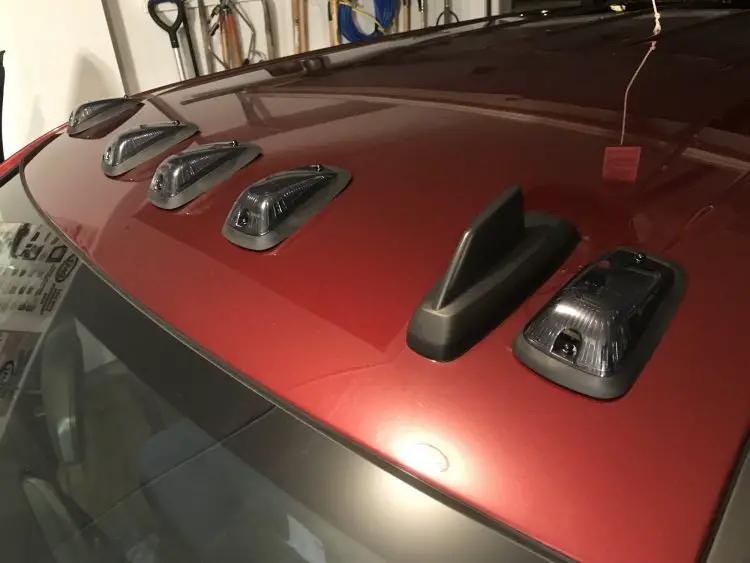

Quick how to and review of the Cab Over America wireless cab lights. Link to parts: https://caboveramerica.com/ The parts: For just under $400 you get a set of 5 battery powered wireless cab lights. Each light consists of 4 parts; the aluminum mounting plate, rubber gasket, LED/PV panel module, and the top lens. The top lenses can be had in clear, amber or smoke. In our case, we went with smoke. You also get two remotes to control the lights. Overall the quality is high and what I would expect from something in this price range. You also get some small lenses that can be place inside the cab lights to change the lights to amber while still using a clear or smoke outer lens. Lastly you are given a Cab Over America tape measure. We laid the tape out but ended up using a tape measure for all measurements. The install: First step was to decide on how you will be playing out the lights. We went with the two edge lights and 3 concentrated in the middle. Others may go with the even spacing all the way across, completely up to you. Here's a test fit. Also shows you the clearance with the shark fin. Remove the two nuts, lens, LED, and gasket so you are just left with the aluminum bracket with screw posts. It was easier to measure and mount the brackets without all the extra parts. We also bent the brackets a bit to fit the counter of the roof in the location they'd be installed. Here they are laid out in position. Wipe down the front 10" of your cab with Isopropyl alcohol. This is to prep the surface for better adhesion. Starting with the cab light nearest to the shark fin, measure 4.5" up from the windshield and 4.5" from the rain gutter to the front stud. This will locate the front mounting post. The rear post of the drivers side cab light should also be 4.5" from the gutter. Using a marker to make temp markings so when you remove the tape backing you can guide the bracket into position. Remove the tape backing, heat up the double stick tape, and install using your guidelines. Repeat for the passenger side light. Find the center of the windshield, measure 4.5" straight back, this will locate the front stud of the center light. Make sure the mounting bracket is straight and mark guide lined with a marker, remove tape backing, heat up the tape, then install. For the side center lights, we offset the lights 7.5" from the center light centerline. Measuring 7.5" from the center light's stud to the side light studs we were able to locate the side lights. Both the front and back studs of the side cab lights are 7.5" from the respective studs on the center light bracket. After all the metal brackets were installed the rubber gaskets were reinstalled, LED modules installed, and the lenses were screwed down. Last step was to sit back and enjoy the lights. They look great with the switchback mirrors! Here is a video of the install if you don't like reading! Thanks! WF41

-

In between packing up our house to move and work I finally found time to pull together my review of the Bumpershellz I installed on my Sierra. I picked up a set of the bedlined bumpershellz for my GMC through the recent group-buy we did on the forum a while back. Side note, thank you to everyone who participated, it was fun. First impression, these things are badass!!! The bedliner was an excellent choice. I was back and forth between doing a PTM or the bedliner, glad I went with the liner version. I have installed body accessories in my tuner days (think, front lips on Civics) and was fully expecting to have to modify the shellz to fit my truck because body panel accessories never fit. These fit right out of the box making life REALLY easy. One note, the adhesive is really tacky so like Eminem says, "You only get one shot, do not miss your chance to-" TEST FIT! TEST FIT! TEST FIT! Final verdict: I would without a doubt install these again if I needed to. Anyways here are some pictures of the final product and my Youtube install video. Water Fowler junior wanted to help and shows that even kids can do this install. Installation sparknotes for the laz: Clean bumper Wipe bumper with isopropyl alcohol Install blackout tape Remove adhesive backing Slap the shellz on the truck Sit back and admire Enjoy!!! WF41 https://youtu.be/YKUyQgOYLNI

- 12 replies

-

- 4

-

-

- ecoological

- waterfowler41

-

(and 5 more)

Tagged with: