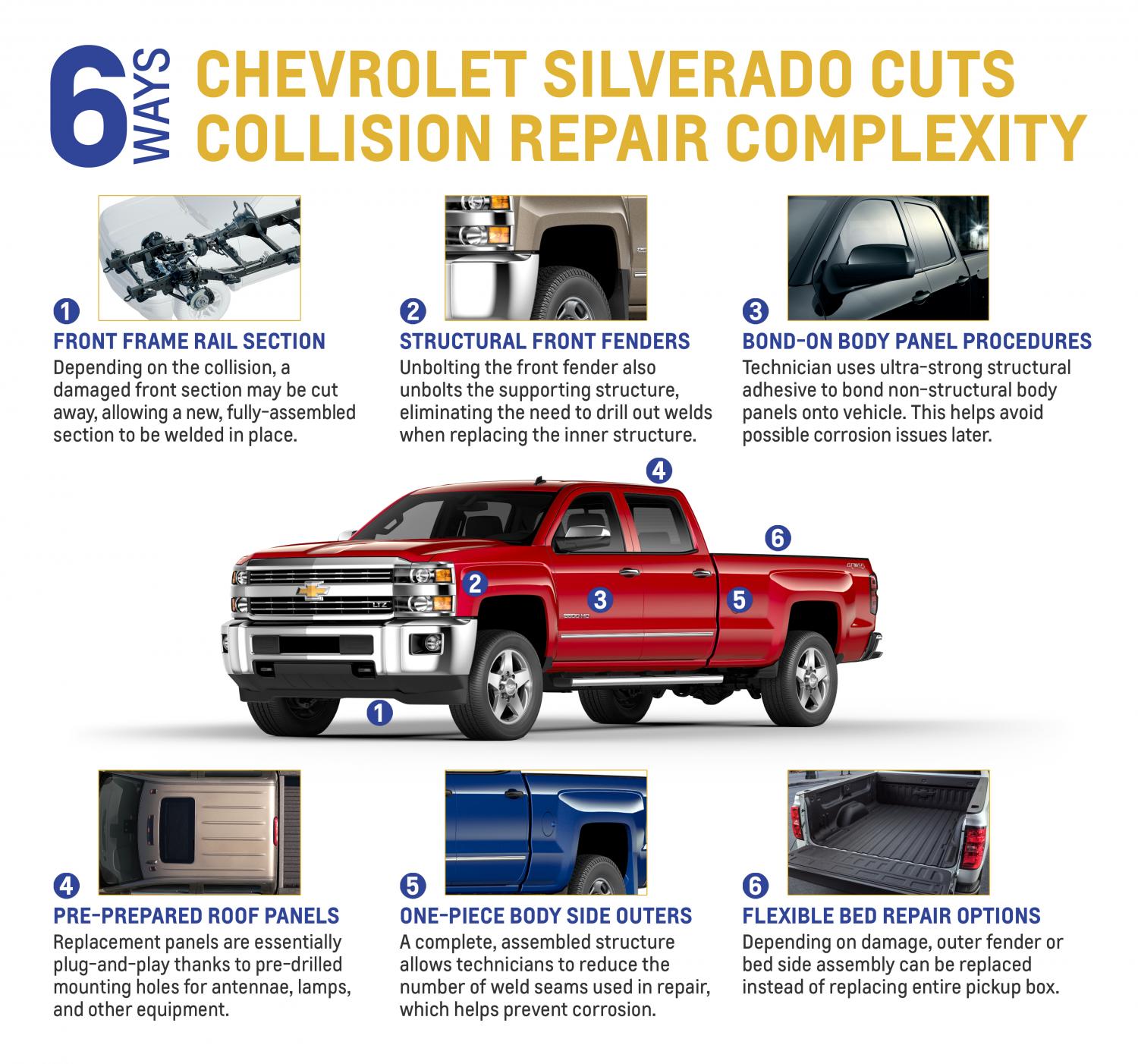

Today Chevrolet released an info-graphic that points out six of the ways that GM engineers designed the Silverado to be more cost effective to repair. Yes, this announcement is timed perfectly to scare Ford F-150 shoppers into thinking aluminum repairs will cost them time and money, but the truth is the Ford F-150 and many other commonplace vehicles have used aluminum body panels for a decade or more. Here are the six things Chevy thinks makes the Silverado easier to repair than competitors' trucks:

Front Frame Rail Section

Chevy says the leading section of its from frame rails may be removed or repaired making it easier to deal with frame damage.

Structural Front Fenders

Chevy designed the front fenders to unbolt in one larger piece, rather than an outer skin and inner supporting piece. This makes font end damage faster and simpler to work on.

Bond-On Body Panel Procedures

Rather than weld, some outer panels can be repaired using construction adhesives.

Pre-prepared roof panels

Chevy pre-drills holes for studs and accessories on its repair roof panels saving repair time.

One-Piece Body Side Outers

Chevy said in its announcement "If damage occurs to the outer panels of the cab, technicians can order a complete body side outer, shipped as a single, complete assembly, allowing technicians to cut out and replace only the damaged area instead of the entire assembly."

Flexible Bed Repair Options

Chevy designed its pickup beds so that owners can repair just the bed or bed box sides. Not all repairs require a full bed box replacement.

Recommended Comments

There are no comments to display.